Pilot project 2 - Digital twin with AI for sustainable and efficient energy management

CHALLENGE! The objective is to construct a digital twin integrated with artificial intelligence that facilitates sustainable and efficient energy management by bridging the gap between energy producers and consumers.

HOW? The proposed approach involves linking a simulation model with the actual physical world and leveraging AI to enable real-time energy management.

WHY? The primary motivation behind this endeavor is to expedite and enhance the decision-making process when it comes to managing energy resources.

FINAL RESULT→ The desired outcome is the development and implementation of a functional digital twin equipped with advanced artificial intelligence capabilities to effectively manage energy consumption in the physical world.

GOALS FOR INNO2MARE PROJECT: The INNO2MARE project aims to leverage digital twin technology, energy management, and artificial intelligence to promote innovation and sustainable development in the maritime industry. The project seeks to develop and implement digital twin solutions that can facilitate efficient and safe energy management in maritime operations, utilizing AI to optimize energy consumption and reduce carbon emissions. Additionally, the project aims to foster collaboration between stakeholders in the maritime industry to drive the development of new technologies and processes that can enhance the performance and sustainability of maritime operations. By achieving these goals, the INNO2MARE project will enable the maritime industry to meet the challenges of the future while promoting innovation and sustainability.

Physical Setup and Prototyping

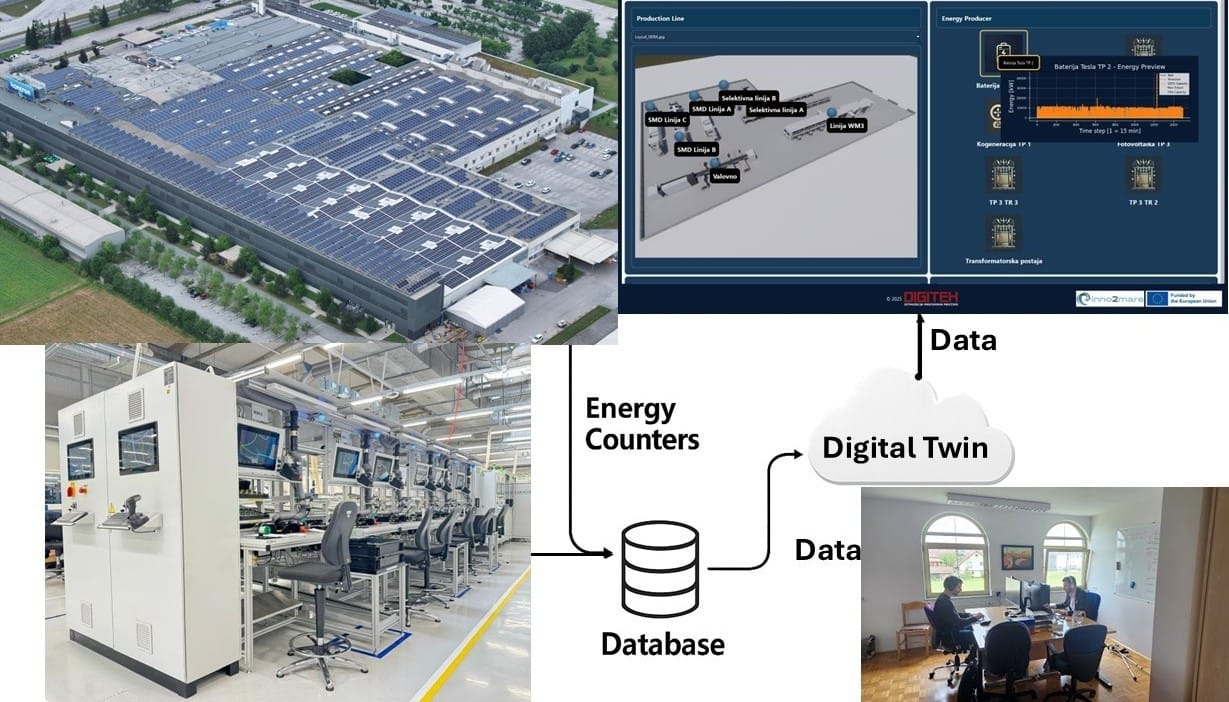

The main infrsatructure of Pilot project 2 is located in Slovenia, particular at partners DIGITEH and ISKRA, while UL has its own Demo lab of factories of the future where developed approaches and results can be integrated, tested and evaluated.

- ISKRA, Ljubljanska cesta 24a, 4000 Kranj

Specializes in physical systems and operational production lines. Offers real-time data collection via cloud servers, integrated solar panels and solar energy systems, cogeneration systems, and battery storage solutions. - DIGITEH, Tržaška cesta 315, 1000 Ljubljana

Provides digital and virtual systems, including PC workstations and specialized hardware and software for developing digital twins of production systems and processes. Offers AI-powered digital twin solutions for sustainable and efficient energy management. - University of Ljubljana, Faculty of Mechanical Engineering, Department of Manufacturing Systems and Processes, Aškerčeva 6, 1000 Ljubljana

Hosts a demonstration lab of a Smart Factory, featuring digital and virtual systems, PC workstations, and various hardware and software tools for developing digital twins of production systems and processes. Includes AI-integrated digital twin solutions aimed at sustainable and efficient energy management.

Recent Developments and Progress

Experiments and actions on the Pilot projects 2 until 30.06.2025

1. Data and HMI

A significant development since the previous milestone was the transition to a new data architecture. We have moved from direct database integration to using a new system based on REST API calls. These API calls are capable of retrieving real-time data, providing a scalable and flexible connection to the data source. However, to ensure stability during the current development phase, data retrieval is still performed only once per day.

Alongside data acquisition, major progress has been made in the development of the Human-Machine Interface (HMI), which now consists of two integrated components: Admin HMI and User HMI.

Admin HMI

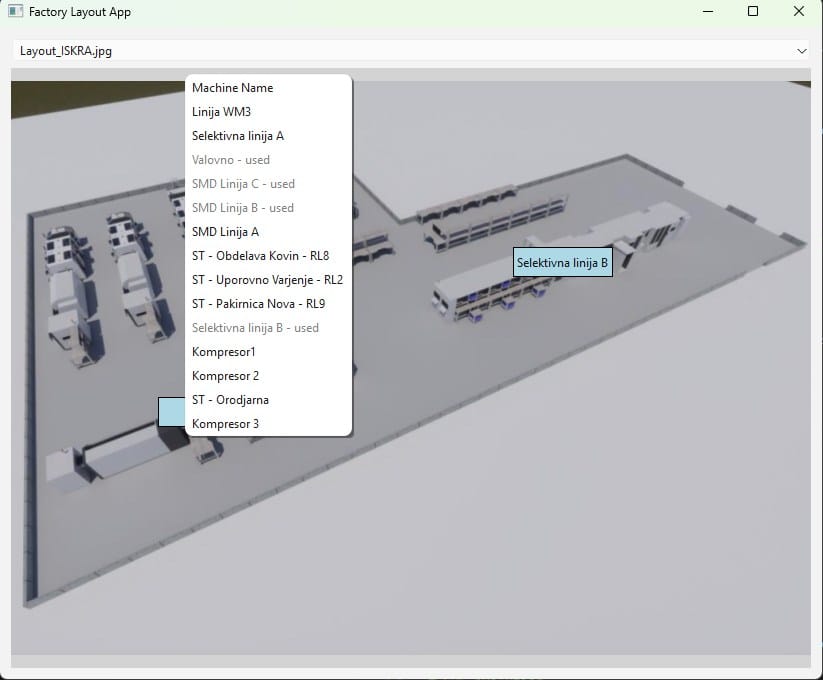

The Admin HMI is designed to configure the factory layout and associate machine data visually as shown in Figure 1. It allows administrators to set up new factory environment or change the already existing one.

This ensures a flexible and scalable method for mapping any production or energy entity onto the layout, supporting consistent rendering in the user interface. To avoid duplication, each production line can be placed only once across all layouts.

User HMI

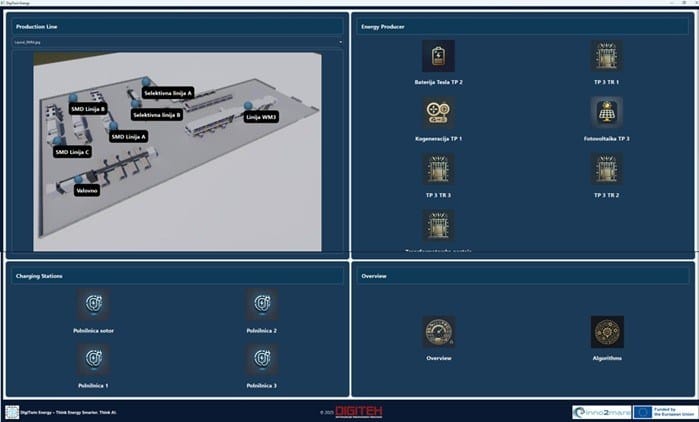

The User HMI provides a streamlined and interactive interface for monitoring the factory’s energy performance and production status. It is built dynamically based on the configuration created in the Admin HMI, ensuring accurate placement and labeling of machines and other entities.

When opening the User HMI, users are first presented with several sections—such as Production Lines, Other Energy Producers, Energy Consumers and Overview, presented in Figure 2. Each section is tailored to the type of data and layout it represents.

In the Production Lines section shown in Figure 3, users can load predefined factory layouts. These layouts display clickable buttons corresponding to each machine, positioned according to the configuration created in the Admin HMI. Clicking on a machine opens a popup that shows real and predicted energy consumption, production quantity, and additional metrics relevant to that production line.

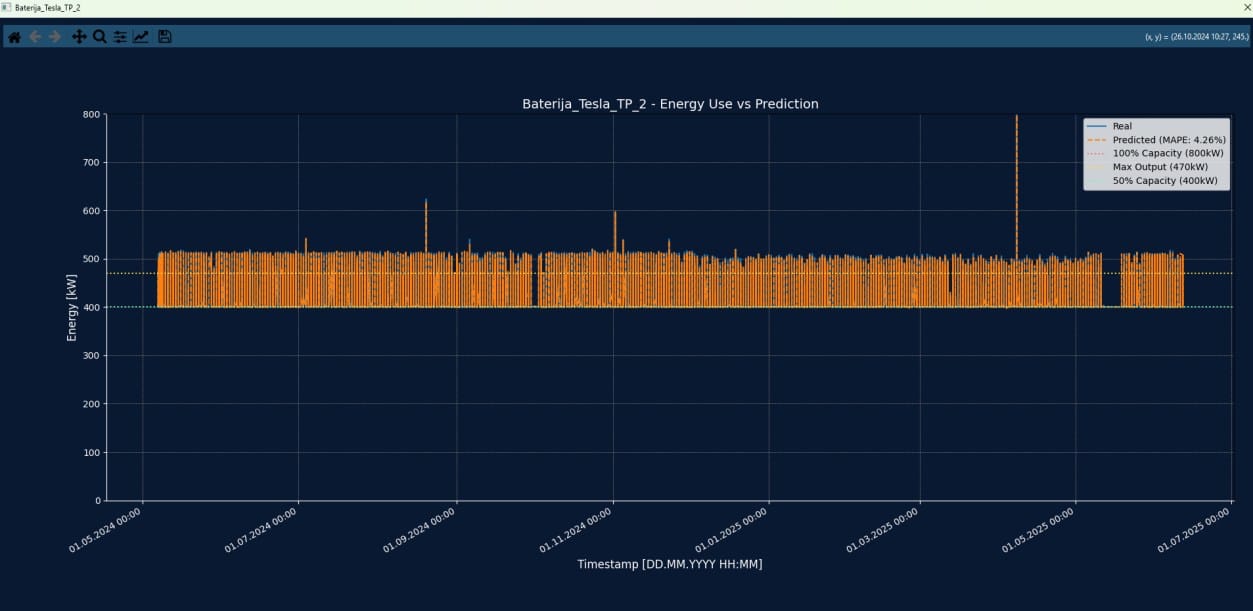

The Energy Producers section includes specialized popups depending on the producer type. For instance, photovoltaic systems display real versus predicted power output, along with environmental context indicators like sun or cloud icons. For batteries and Tesla units, additional reference lines indicate thresholds such as maximum capacity and 50% charge levels as seen in Figure 4.

Each popup provides zoomable line charts that allow users to inspect historical trends and forecasts in greater detail. Navigation between sections is straightforward, and the interface ensures that only valid, non-duplicated entities are displayed per layout.

The Overview section provides a high-level summary of the factory’s energy performance and upcoming management strategy. It contains two main views: Overview and Algorithms.

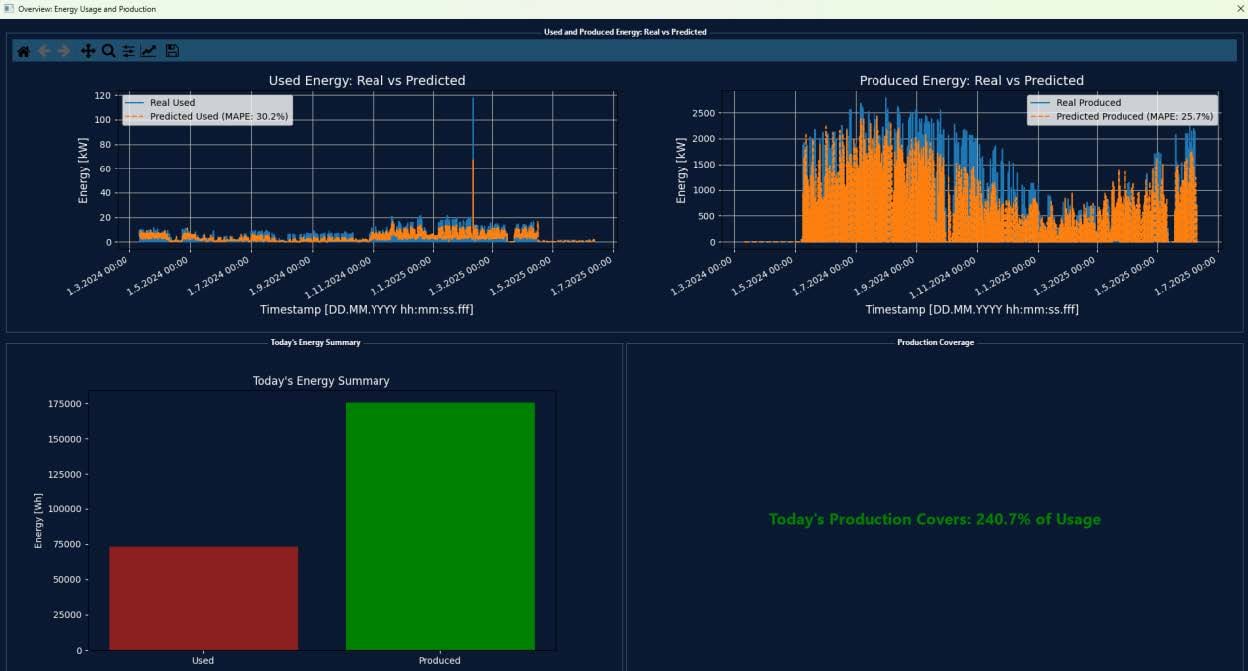

In the Overview view, users can see the total energy used and produced for the current day, along with the percentage of consumed energy that is covered by internal production. This gives a quick insight into the factory’s energy self-sufficiency and efficiency.

The Algorithms view displays the planned energy management strategy for the next 48 hours. This includes a visual representation of how different energy sources—such as grid, battery, photovoltaic, and cogeneration—will be used to meet expected consumption, based on forecasted data and optimization results.

2. Anomalies in Energy Data

With the transition to the new database and REST API-based data collection, several anomalies were detected in the incoming energy data. These included missing timestamps and abnormal spikes, often caused by temporary counter shutdowns or interruptions in data transmission. The data processing pipeline was updated to automatically detect and correct such inconsistencies, ensuring reliable input for the digital twin. These improvements help prevent distorted results in energy predictions and management strategies.

3. Advances in Digital Model

The digital twin model has seen significant technical enhancements, particularly in simulation continuity and intelligent decision-making. The simulation logic was upgraded to automatically detect and import only new data, allowing the system to resume from the last processed timestamp instead of restarting from the beginning. This improvement greatly enhances simulation speed and scalability. The research to transition from Technomatix Plant Simulation to Python based Digital twin for easier integration in different user systems was also done.

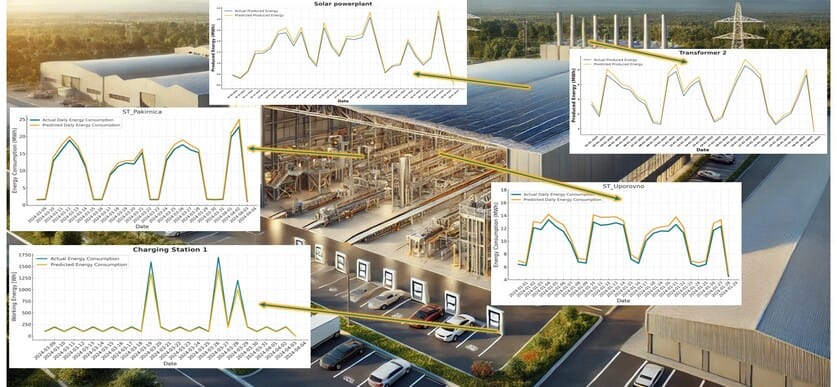

Neural Network-Based Prediction

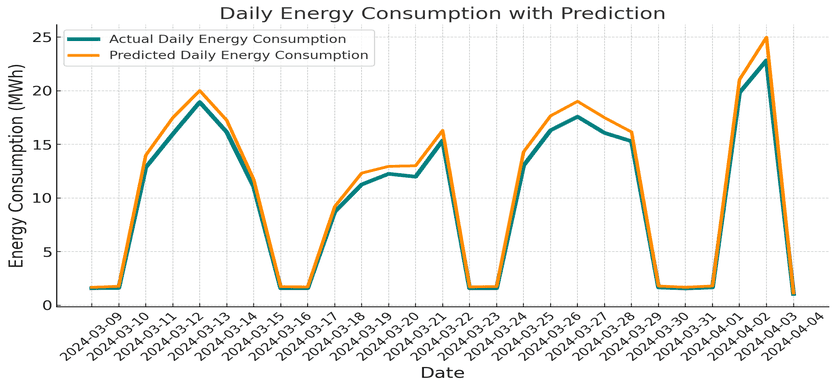

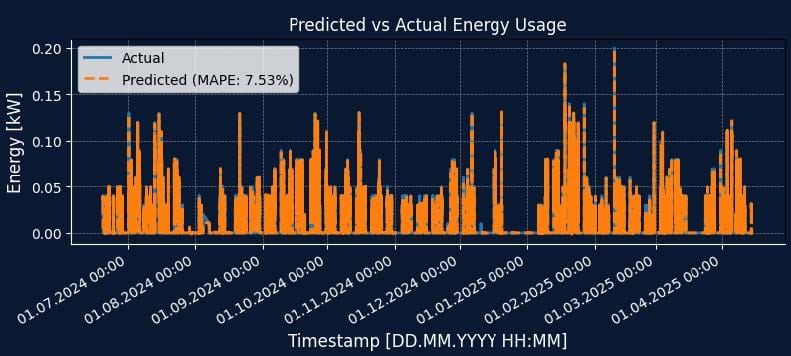

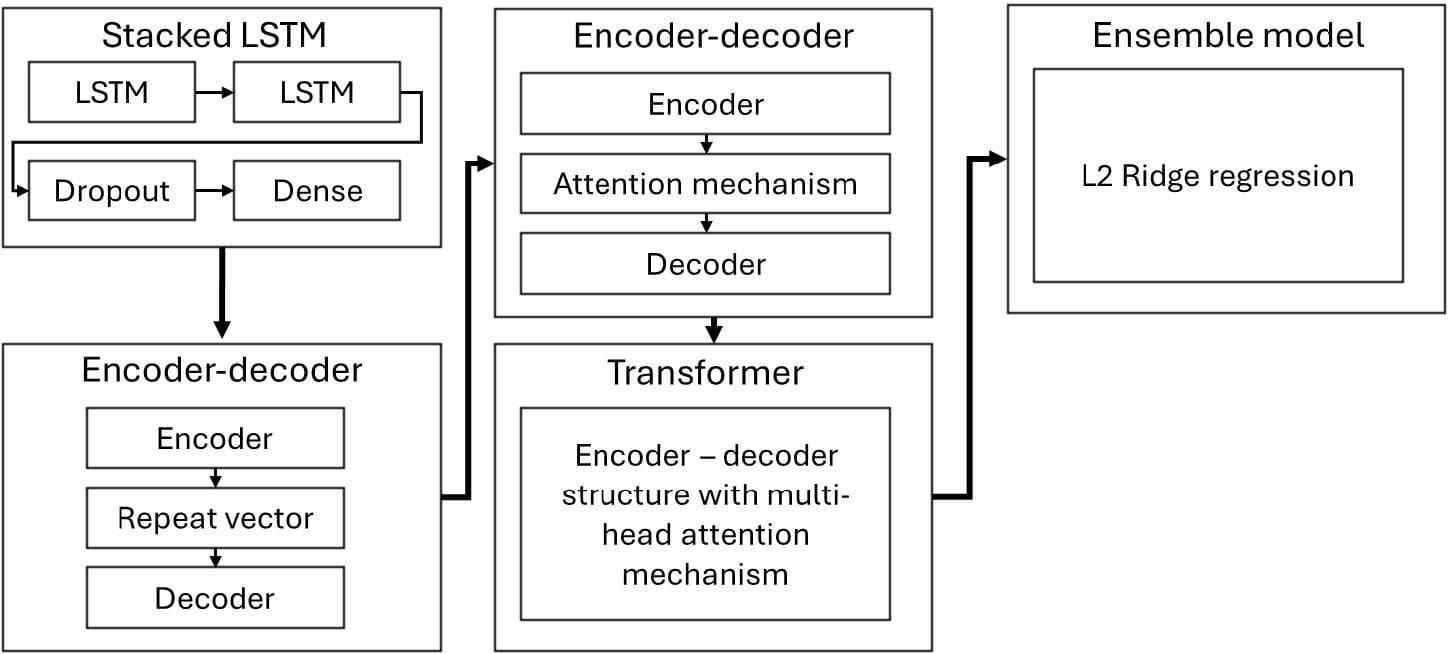

The development of predictive models has followed a progressive path, moving from basic architectures to advanced ensemble methods. Initial experimentation began with stacked LSTM networks, which provided a solid baseline for capturing temporal patterns in energy data. Building on this, the team implemented an encoder-decoder LSTM architecture, enabling multi-step forecasting over a 48-hour horizon. Figure 6 presents results of comparison between predictions and real values for one machine in production line section.

To improve accuracy and temporal alignment, attention mechanisms were introduced, allowing the model to focus on the most relevant time steps when generating forecasts. This was followed by the development of a Transformer-based model, which significantly improved the system’s ability to capture complex seasonal trends, sharp peaks, and irregular consumption patterns—especially across production shifts and energy generation variability.

Finally, to leverage the strengths of each architecture, an ensemble model was implemented. This model combines the outputs of the LSTM, attention-based LSTM, and Transformer models using a meta-learner, resulting in more robust and stable predictions. The ensemble output is now used as the primary input for downstream energy management, offering both short-term accuracy and resilience to anomalies or rapid operational changes. The accuracy afforded by our ensemble model is up to 95%, meaning our predictions at best can deviate only 5% from real values – a very good result for timeseries predictions. The development of algorithms is shown as a block diagram in Figure 7.

These predictive models are trained on real production and consumption data and updated regularly, ensuring the digital twin can anticipate factory behavior and enable proactive planning.

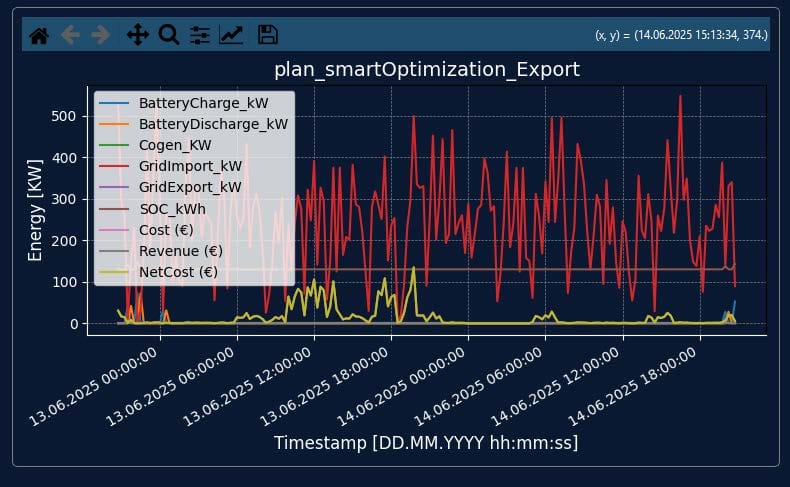

Energy Management Optimization

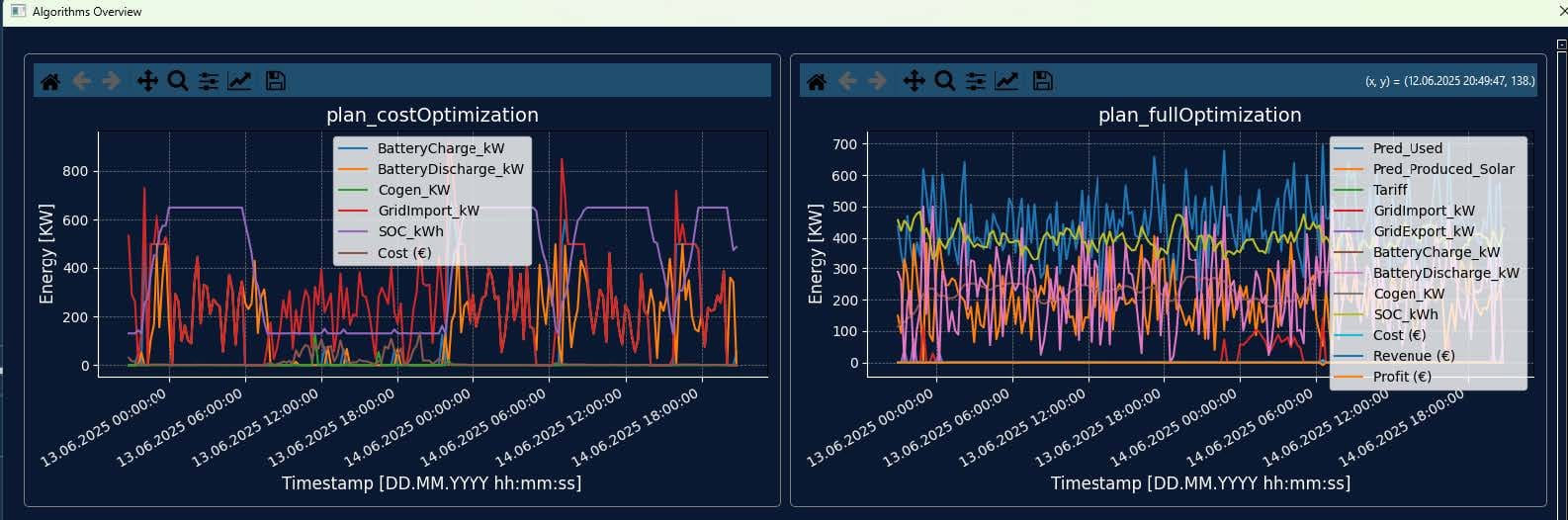

Building on the predictive forecasts, a dedicated energy management module determines the optimal strategy for using available energy sources across a 48-hour horizon. Two types of optimization algorithms were developed and tested:

- The greedy algorithm, which evaluates energy decisions over short, rolling windows, prioritizing immediate benefits without considering long-term outcomes.

- The more advanced smart algorithm, which performs full-period optimization across the entire 48-hour forecast, enabling globally optimal decisions based on future trends and constraints.

These algorithms optimize not just energy flow, but also the sequence in which different energy sources are used—balancing grid power, battery storage, cogeneration, and renewables. The system supports two core objectives:

- Cost minimization, which reduces total electricity expenditure.

- Profit maximization, which aims to maximize net financial gain from energy production and export opportunities.

Additional considerations include strategies for extending battery life, such as limiting deep discharge cycles and avoiding unnecessary charge fluctuations, which are factored directly into the optimization logic.

The final optimized strategy is recalculated every 24 hours and visualized within the HMI, allowing users to monitor upcoming energy plans and better understand the rationale behind system behavior. This establishes a robust, closed-loop digital twin capable of predictive, constraint-aware, and goal-driven energy management. Figures 8, 9, 10 present partial HMI views of different energy management algorithms and their visualisation of energy sources usage.

4. Conclusions and Next Steps

Significant progress has been achieved in developing the digital twin, particularly in the areas of data integration, visualization, predictive modeling, and energy optimization. The transition to a real-time-capable database infrastructure has resolved prior data anomalies, ensuring clean and consistent input for simulation and forecasting. The Human-Machine Interfaces (HMI) for both users and administrators have matured into powerful tools for monitoring operations, visualizing predictions, and managing factory layouts.

The evolution of predictive algorithms—from simple LSTMs to attention-based models, Transformers, and ultimately ensemble approaches—has resulted in reliable 48-hour forecasts for both energy consumption and production. These forecasts now serve as input for advanced energy management algorithms, which plan and optimize energy usage under real operational constraints. Both cost-minimizing and profit-maximizing strategies are supported, contributing to smarter, more efficient energy use.

Next steps include:

- Finalizing full integration of the digital twin into ISKRA Kranj and ISKRA Šebenik, with support for live data and daily updates.

- Transitioning to Python based Digital Twin.

Progress

Progress 30.6.2023

Progress 31.12.2023

Progress 30.6.2024

Progress 31.12.2024

Progress 30.6.2025

Lesson learnt and implementation strategy

Publications

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

A Robust Heuristics for the Online Job Shop Scheduling Problem

Hugo Zupan , Niko Herakovič , Janez Žerovnik , A Robust Heuristics for the Online Job Shop Scheduling Problem

Published in: MDPI , Algorithms 2024, 17, 568, https://doi.org/10.3390/a17120568

Abstract:

The job shop scheduling problem (JSSP) is a popular NP-hard problem in combinatorial optimization, due to its theoretical appeal and its importance in applications. In practical applications, the online version is much closer to the needs of smart manufacturing in Industry 4.0 and 5.0. Here, the online version of the job shop scheduling problem is solved by a heuristics that governs local queues at the machines. This enables a distributed implementation, i.e., a digital twin can be maintained by local processors which can result in high speed real time operation. The heuristics at the level of probabilistic rules for running the local queues is experimentally shown to provide the solutions of quality that is within acceptable approximation ratios to the best known solutions obtained by the best online algorithms. The probabilistic rule defines a model which is not unlike the spin glass models that are closely related to quantum computing. Major advances of the approach are the inherent parallelism and its robustness, promising natural and likely successful application to other variations of JSSP. Experimental results show that the heuristics, although designed for solving the online version, can provide near-optimal and often even optimal solutions for many benchmark instances of the offline version of JSSP. It is also demonstrated that the best solutions of the new heuristics clearly improve over the results obtained by heuristics based on standard dispatching rules. Of course, there is a trade-off between better computational time and the quality of the results in terms of makespan criteria.

Keywords: job shop scheduling problem; online algorithm; heuristics; simulation; digital twin; smart manufacturing

Towards Improving Automated Testing with GraphWalker

Yavuz Koroglu; Mutlu Beyazıt; Onur Kilincceker; Serge Demeyer; Franz Wotawa, Towards Improving Automated Testing with GraphWalker (https://ieeexplore.ieee.org/abstract/document/10962480)

Published in: IEEE International Conference on Software Testing, Verification and Validation Workshops (ICSTW), Naples, Italy, 2025, pp. 54-58,

DOI: 10.1109/ICSTW64639.2025.10962480

Abstract:

GraphWalker is a widespread automated model-based testing tool that generates executable test cases from graph models of a system under test. GraphWalker implements only two random test generation algorithms and has no optimization-based algorithm, where an evaluation of its performance in test lengths and coverage remains an open question in the literature. In this work, we performed experiments on three realistic systems to evaluate redundancy, coverage, and length of GraphWalker test cases. The experimental results show that even the best GraphWalker test cases are highly redundant, limited in edge pair coverage, and need significantly longer test cases to increase edge pair coverage. Overall, we establish a baseline to compare future optimization-based algorithms with, while the amount of improvement and its impact are important research questions for the future.

Keywords: software testing, test generation, model-based testing, graph coverage

Integrating Digital Twin Technology to Achieve Higher Operational Efficiency and Sustainability in Manufacturing Systems

Matevž Resman, Niko Herakovič, Mihael Debevec, Integrating Digital Twin Technology to Achieve Higher Operational Efficiency and Sustainability in Manufacturing Systems

Published in: MDPI, Systems 2025, 13(3) ,180 https://doi.org/10.3390/systems13030180

Abstract:

Digital twin technology has proven to be a transformative tool in the development of smart factories by providing real-time data-driven simulations and virtual representations of physical assets and systems. This paper explores the integration of digital twins in the context of Industry 4.0 and sustainability, highlighting their potential to increase operational efficiency, optimize material usage and minimize waste. To demonstrate these benefits, case studies are presented in which a digital twin of a real manufacturing system was implemented. The digital twin enabled us to run different “what-if” scenarios to evaluate the improvements in the manufacturing system, efficiency and reduction of raw material consumption and waste by incorporating quality control operations at all assembly stations. Based on the analysed results of both case studies, we demonstrated that additional quality control operations had a significant impact on the efficiency of the manufacturing system and its sustainability, as waste was significantly reduced. The proposed approach has proven to be highly effective for different types and sizes of manufacturing systems, especially those with high waste generation.

Keywords: sustainable manufacturing; digital twin; waste reduction; smart manufacturing; digital environment; simulation; methodology

Automated Generation of Simulation Models and a Digital Twin Framework for Modular Production

Filip Jure Vuzem, Miha Pipan, Hugo Zupan, Marko Šimic, Niko Herakovič, Automated Generation of Simulation Models and a Digital Twin Framework for Modular Production

Published in: MDPI , Systems 2025, 13(9), 800; https://doi.org/10.3390/systems13090800

Abstract:

This study presents the development of a Digital Twin (DT) framework that is capable of generating and adjusting simulation models of production processes and systems automatically and in real-time. A Machine Vision (MV) system is used to detect newly added or already existing production module locations and rotations, as well as changes in both their location and rotations. This subsystem primarily functions as an External database and is used for new Asset Administrative Shell (AAS) creation, housing, and data gathering, which also includes a visualization platform. Tecnomatix Plant Simulation (TPS) is used for simulation model building, simulation execution, and high-level scheduling based on work orders and technological plans. Different subsystems were integrated into the DT framework using fast and reliable communication protocols. The automation of the proposed framework significantly reduces manual intervention, thus eliminating human factors, reducing the time needed for model creation, improving simulation fidelity, and providing the fundamentals for robust connectivity within the DT framework. The findings highlight the transformative potential of this method for streamlining simulation processes and enhancing system adaptability in complex environments.

Keywords: production layout ; Digital Twin framework; simulation ; self-building; attributes; parameters; connectivity